ELECTRIC ACTUATORS

ELECTRIC ACTUATORS

VFD Controlled Electric Actuators

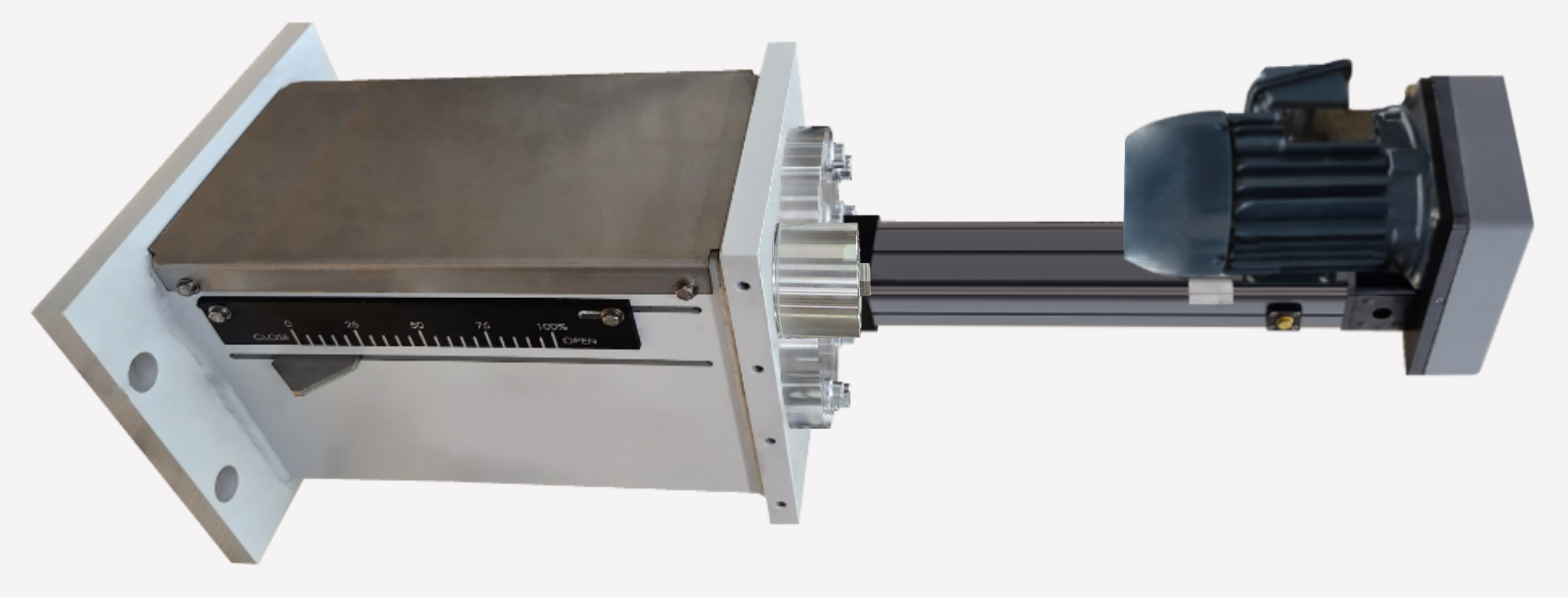

BLAC INC. Viper Series Electric Actuators are designed for both modulating and on-off applications.

Viper actuators utilize a VFD controlled bi-directional motor to operate a linear output cylinder drive with zero backlash when changing directions.

Viper applies the BLAC INC. patented hydraulic actuator cylinder rod seal to prevent contamination of the drive cylinder internals. The VFD controller uses position feedback to indicate the controlled position while continuously maintaining the valve command position.

Viper Electric Actuator

Viper Advantages

VFD Over Servo Drives

Cost-Effective Control: Lower cost than servo driven electric systems.

Application-Level Precision: Delivers precise control for most applications.

Simplified Integration: Directly controls the voltage and frequency supplied to the motor.

Electric Over Hydraulics/Pneumatics

Reduced Maintenance: Induction motor does not have the maintenance requirements of hydraulics or pneumatics.

Demand-Based Power: Reduced energy consumption.

Compact Design: Rugged, closed system.

Viper Features

Precise modulating control using VFD

Positioning control, accuracy, linearity and repeatability of <0.1% stroke under a varying load

All-electric actuator without gears

Linear rising stem and slide valve actuators

Fail in position with zero drift

Fail to end of stroke position by spring or by UPS supplied system

On-Off applications

Can be wired to replace MOV applications

All worldwide electrical hazardous area classification

Corrosion free construction materials of stainless steel and anodized aluminum

Mounts in place of a pneumatic or hydraulic cylinder

Performs equivalent to electro-hydraulic actuators

Viper Linear Rising Stem

Viper Accessories

Available accessories include handwheel, limit switches, and multiple feedback devices designed for any hazardous area classification.

Shown is a Viper for FCC slide valve service.

Viper including handwheel, limit switches,

and feedback devices

Viper Data Sheet

| Item | Viper Details |

|---|---|

| Command Signals | 4-20 mA, On-Off Digital |

| Feedback Signals | 4-20 mA |

| Normal Thrust | <2000 lbf (<8896 N) to 80,000 lbf (355,858 N) |

| Stroking Speed | 0.5 in/sec (12.7 mm/sec) |

| Hysteresis/Linearity/Repeatability | 0.1% of span (under load) |

| Sensitivity/Dead Band | 0.1% of span (under load) |

| Ambient Conditions | -40 to 130°F (-40 to 54°C) |

| Area Electrical Classification |

IECEx, ATEX and NEC |

| Actuator Travel | 1.5 to 48 in (38 to 1220 mm) |

| Motor Voltage Primary | 220-600 VAC, 3 Phase |

| Motor Voltage Option | 115/230 VAC, 1 Phase |

| Instrument Power | 24 VDC or 110/220 VAC, 1 Phase |

| Item | Viper Details |

|---|---|

| Command Signals | 4-20 mA, On-Off Digital |

| Feedback Signals | 4-20 mA |

| Normal Thrust | <2000 lbf (<8896 N) to 80,000 lbf (355,858 N) |

| Stroking Speed | 0.5 in/sec (12.7 mm/sec) |

| Hysteresis/Linearity/Repeatability | 0.1% of span (under load) |

| Sensitivity/Dead Band | 0.1% of span (under load) |

| Ambient Conditions | -40 to 130°F (-40 to 54°C) |

| Area Electrical Classification |

IECEx, ATEX and NEC |

| Actuator Travel | 1.5 to 48 in (38 to 1220 mm) |

| Motor Voltage Primary | 220-600 VAC, 3 Phase |

| Motor Voltage Option | 115/230 VAC, 1 Phase |

| Instrument Power | 24 VDC or 110/220 VAC, 1 Phase |

Viper Product Specifications

For specific sizing criteria, contact us for details.

Viper Electric Actuator - Linear Application